Many readers have asked us about the difference between felt, prefelt, pannolenci (a kind of lightweight felt) and boiled wool. The readers’ interest in this matter grew after we published the article about prefelt by Maria Friese.

So, I would like to shed some light on this topic. For many of you, this is going to be just a review of something you already know, but for those who have just entered this fascinating universe, it may be the first chance to learn about the differences between these materials.

First of all, boiled wool is a knitted fabric. Boiled wool is made through a process called fulling. The fabric is put into a fulling machine, which soaks the material in an alkaline-soapy solution, and then makes the fibers stick together by mechanically compressing them. Thanks to this process, the fabric becomes more resistant, more compact and fairly waterproof.

Felt is a non-woven fabric. That is, a textile whose structure is NOT characterized by a warp and a weft. It is not made through weaving. In making felt, whether on an industrial level or by hand, we take advantage of a morphological peculiarity of wool: its scaly surface. If processed with a specific procedure (which involves water, soap and a vigorous mechanical treatment) wool tends to “lock”, to felt. That is because its superficial scales tend to open, and then latch into each others and close again.

Felt can be cut, sewn, glued just like any woven fabric. Actually, with handmade felt, you can even create 3D shapes and clothing without having to sew anything.

If you want to learn more about handmade felt, please take a look at the many DHG Tutorials.

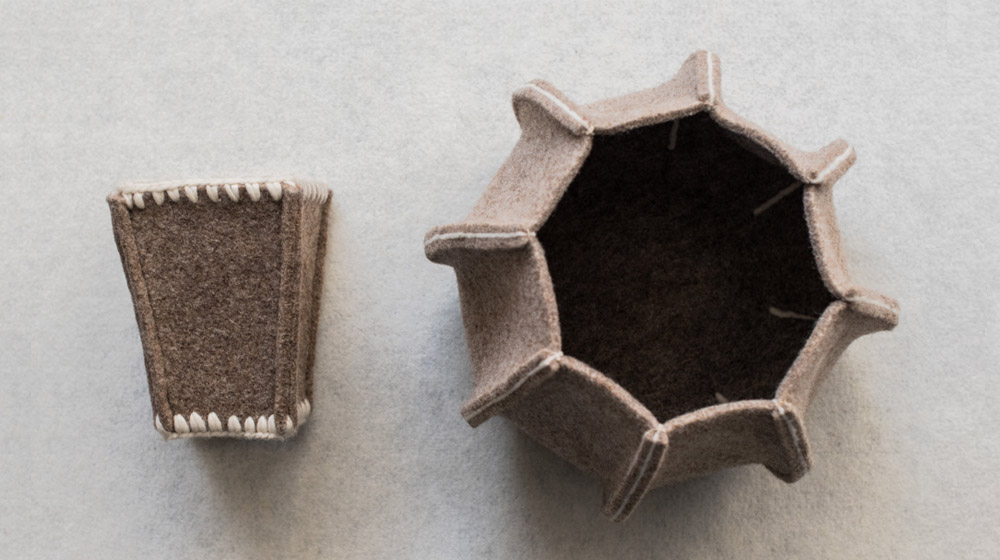

In the picture below, you can see how some industrial felt was used to make a fruit bowl and a pen holder.

Below, you can see some items made with handmade felt.

If you browse forums and sites around the web, you’ll read that Pannolenci is, like felt, a non-woven fabric made with carded wool fibers, only with a different thickness and weight.

When we came across that definition, we thought it was incomplete, misleading and far from scientific. Indeed, a mere difference in thickness is certainly not a technical feature which can be considered enough to distinguish one textile product from another.

With the help of our colleagues at DHG, like modern Indiana Jones we tried to investigate the subject and we interviewed some experts in the field. Here is what we found out.

The word pannolenci was first used in Italian around 1920. That is when a Turin company called Lenci created a cloth (“panno” in Italian) that was compact, soft and very, very thin, and did not fray when cut (as it had no warp or weft).

Considering the type of textile machinery in use at the time, we are inclined to think that the product was made with the same technology used for making the thicker varieties of felt that were already available on the market. This hypothesis is confirmed by the description of the productive process, according to which pannolenci was made by needle felting carded wool fibers, just like felt.

So, technically, the pannolenci made this way was essentially felt, although a very thin kind.

Then why call it pannolenci rather than lightweight felt?

We should ask those who invented it, but unfortunately that is not possible. We suppose that the idea was to create a sort of brand name connected to the company that made it, Lenci.

For this reason, the name of the company was combined with the word panno (cloth), a very evocative word. Indeed, at that time the word panno indicated in Italian (as it still does) a specific kind of wool fabric that was fulled and felted to make it waterproof, and then gauzed to make one side furry.

Even though pannolenci could look like a “panno” (a fulled cloth), that is technically not quite right, because cloth is in fact a woven fabric, characterized by a plain weave.

Prefelt is a non-woven fabric. As the prefix pre- suggests, it a partially felted product. The production process, whether on an industrial level or handmade, takes advantage of the scaly surface of the wool (just like it happens with felt). However, the process is stopped before the felting is complete.

Industrial prefelt is used in hand felting to speed up the process. Indeed, prefelt serves as a base, which otherwise the felt artist would have to make entirely by hand.

In addition, the fact that it is only partially felted allows the fibers to latch onto each other just enough for the material to be easily cut and handled, almost as if it were a piece of fabric. This allows the artist to make clean cut shapes and ornaments. Such ornaments can be used on their own or to decorate prefelt bases.

A wonderful post with more information about this product is the one Andrea Noeske Porada kindly wrote for us, explaining how to use prefelt.

Whether you use it as a base to work on, or to make ornaments, prefelt must always be felted in the end. This will make it more resistant and, in case it is combined with textiles or decorations, will make them stick to the base. That is exactly the technique Maria Friese uses for her amazing works.

So this it for this article about the differences between felt, prefelt, pannolenci and boiled wool. Before I leave you, I would like to recommend another post in addition to those I have already mentioned: the article by Eva Basile about boiled wool, in which she explains all the tricks of the trade. Enjoy!

WRITE A COMMENT